VÄLKOMMEN TILL AKTIEBOLAGET SERVUS!

Vi marknadsför ett brett sortiment av verktygsmaskiner, järnvägsprodukter, märkutrustningar, kompletta system för spårbarhet samt utför service och utbildning med egen personal, till ett stort antal stora och små företag inom verkstadsindustrin.

AKTUELLT

MÄSSOR

NYA LEVERANSER

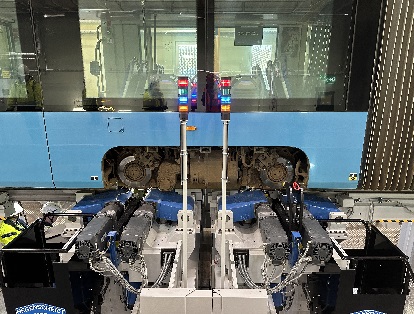

Bilderna visar en HEGENSCHEIDT U2000-150 Tandem hjulsvarv för svarvning av Göteborgs Spårvägars alla spårvagnshjul.

Svarvanläggningen finns i den nya Spårvagnsdepån Ringö som Skanska bygger åt Västra Götalandsregionen, Västfastigheter.

08-446 60 28

08-446 60 28

08-446 60 28

NYA LASIT ROTOMARK X LASERMÄRKSYSTEM

NYA LASIT ROTOMARK X är en kompakt allround-, automatiseringsvänlig noggrann maskin. Denna mångsidiga maskinen kan användas för märkning och verifiering av en bred sortiment artiklar. Naturligtvis har den det höga positionerings-noggrannheten som LASIT är känd för, samtidigt som den har högsta repeterbarheten för pålitlig produktivitet.